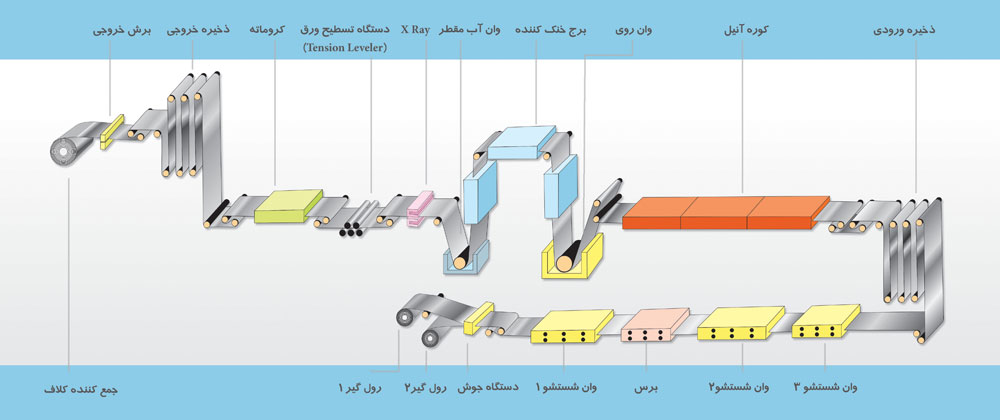

Process of galvanizing steel :

Iron and steel are widely used due to durability and ease of production and assembly.

Corrosion is the main reason of steel fracture and destruction and it is important to be prevented .Steel has a high tendency to absorb oxygen which causes corrosion and chemical composition with oxygen.

Continues Hot-dip galvanizing is a method of steel coating with a layer of molten zinc by immersing the cold rolled coils in a bath of molten zinc.

At the beginning of galvanizing line the input cold rolled coils are welded together to form a continuous strip.

The surface of Steel is cleaned by degreasing with alkaline substances, brush and cleaning with hot water then dried by compressed hot air. Then according to product application, the cleaned coils are annealed during three stages (preheating, heating and isothermal) to be prepared for entry to the zinc pot.

In the zinc pot an electrochemical cell is formed between iron and zinc. In which zinc is used instead of iron as anode and iron as cathode. Zinc oxidizes in anode due to its higher activity, less revival potential and more oxidation potential comparing to iron, and consequently prevents corrosion of the iron.

After exiting the pot a thin layer of zinc will be placed on both sides of sheet. The thickness will be adjusted by air knife immediately.

The temperature of the zinc coated steel is decreased by cooling tower and then Reaches the environment temperature by entering distilled water pot.

Thickness of coating is determined by x-ray device.

Then sheets are passed through the Tension leveler to smooth the sheets, correct probable curvature of sheet's edge and eliminate the waves.

In order to prevent Galvanized sheets from efflorescing during storage, chromate operation will be conducted in which the sheets will be passed through dissolved containing chromium (Cr), to create a thin layer of that on the surface of sheet.

For continuity of coating operation on the surface of the sheet, accumulator towers are considered in both input and output sections.

At the end, after cutting the sheets, galvanized coils with desired weights will be packed and presented to the market.

|